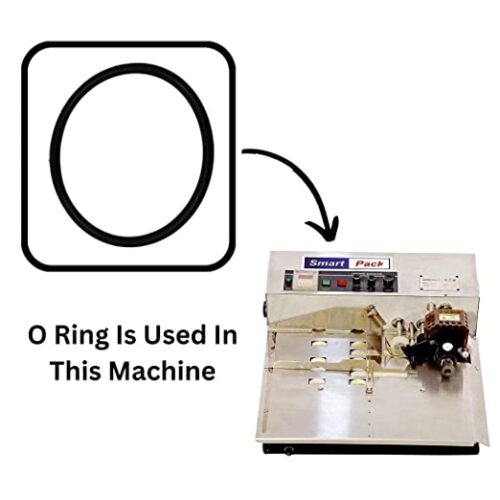

Designing a carbon brush assembly for a high-speed batch coding machine involves several steps to ensure proper function and durability. Carbon brushes are commonly used in electrical machines to provide a sliding contact between a stationary wire and a rotating shaft, typically used in motors or generators. Here’s a general guide on how to design a carbon brush assembly:

- Determine Requirements: Understand the requirements of your high-speed batch coding machine. Consider factors such as voltage, current, operating speed, environmental conditions, and expected lifespan of the carbon brushes.

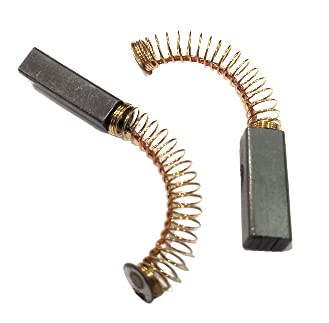

- Material Selection: Choose suitable materials for the carbon brushes based on the application requirements. Carbon brushes are typically made from carbon graphite or electrographite, which offer good electrical conductivity, low friction, and high temperature resistance.

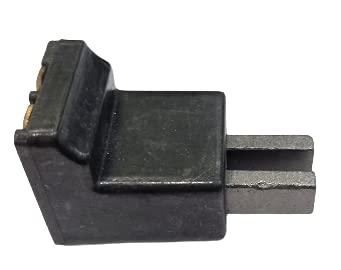

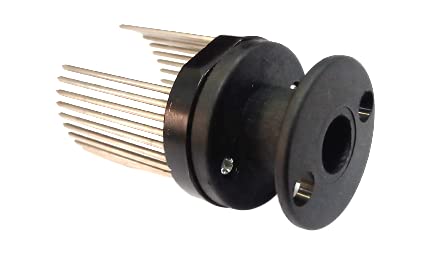

- Brush Design: Design the shape and size of the carbon brushes to ensure proper contact with the rotating shaft of the machine. Consider factors such as brush length, width, thickness, and contact surface area. The design should facilitate efficient transfer of electrical current and minimize wear on both the brush and the shaft.

- Housing Design: Design a housing or holder for the carbon brushes to secure them in place and provide support during operation. The housing should allow for easy installation and replacement of the brushes when necessary.

- Spring Mechanism: Incorporate a spring mechanism or tensioning system to ensure constant pressure between the carbon brushes and the rotating shaft. This helps maintain a reliable electrical connection and prevents arcing or sparking.

- Mounting: Design the carbon brush assembly to mount securely onto the batch coding machine. Consider factors such as mounting location, alignment, and accessibility for maintenance.

- Insulation: Provide adequate insulation between the carbon brushes and other components of the batch coding machine to prevent electrical shorts or interference.

- Testing and Optimization: Prototype the carbon brush assembly and conduct testing to evaluate its performance under various operating conditions. Make any necessary adjustments or optimizations to improve brush lifespan, electrical contact, and overall reliability.

- Manufacturing: Once the design is finalized, manufacture the carbon brush assembly using suitable manufacturing processes such as machining, molding, or 3D printing. Ensure that the manufacturing process maintains tight tolerances and high-quality standards.

- Installation and Maintenance: Install the carbon brush assembly onto the batch coding machine according to the manufacturer’s instructions. Establish a regular maintenance schedule to inspect and replace the brushes as needed to ensure optimal performance and longevity.

By following these steps, you can design and implement a carbon brush assembly that meets the requirements of your high-speed batch coding machine, providing reliable electrical contact and minimizing wear on critical components.

Reviews

There are no reviews yet.