Horizontal Band Sealer Machine is a type of packaging equipment used to seal various types of pouches horizontally. These machines are commonly employed in industries such as food packaging, pharmaceuticals, cosmetics, and others. The Horizontal Band Sealer is particularly versatile and can handle a range of materials including LD (Low-Density Polyethylene), PP (Polypropylene), laminate, and silver pouches. Here are some key features and functionalities of this machine:

- Horizontal Sealing: As the name suggests, the machine seals pouches horizontally, typically sealing the top edges of the pouches.

- Continuous Sealing: Horizontal band sealers are designed for continuous operation, allowing for high-speed sealing of pouches as they move along a conveyor belt.

- Adjustable Conveyor: The machine usually features an adjustable conveyor belt speed to accommodate different types of pouches and sealing requirements.

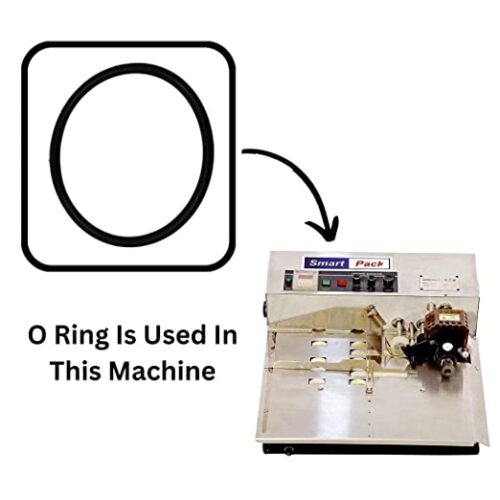

- Sealing Band: Utilizes a heated sealing band to melt and seal the edges of the pouches together. The temperature and pressure of the sealing band are adjustable to ensure proper sealing of different materials.

- Versatility: Horizontal band sealers are versatile and can seal a variety of materials including LDPE, PP, laminates, metallic foils, and other heat-sealable films.

- Temperature Control: Equipped with temperature control systems to maintain the appropriate sealing temperature for different types of packaging materials.

- Variable Seal Width: Some models offer adjustable sealing width options to accommodate different pouch sizes and sealing requirements.

- Integrated Printing: Some machines may come with an optional printing attachment for printing batch numbers, expiration dates, or other information directly onto the pouches during the sealing process.

- Ease of Use: Designed with user-friendly controls and an intuitive interface for easy setup and operation.

- Durable Construction: Built with sturdy materials to withstand continuous use in industrial environments, ensuring long-term reliability.

- Optional Features: Depending on the model and manufacturer, optional features such as gas flushing (MAP – Modified Atmosphere Packaging) capability or vacuum sealing may be available to extend the shelf life of packaged products.

- Maintenance: Regular maintenance such as cleaning, lubrication, and periodic replacement of sealing bands is necessary to ensure optimal performance and longevity of the machine.

Overall, Horizontal Band Sealer Machines are efficient and reliable solutions for sealing various types of pouches horizontally, offering versatility, speed, and consistent sealing quality for a wide range of packaging applications.

Reviews

There are no reviews yet.