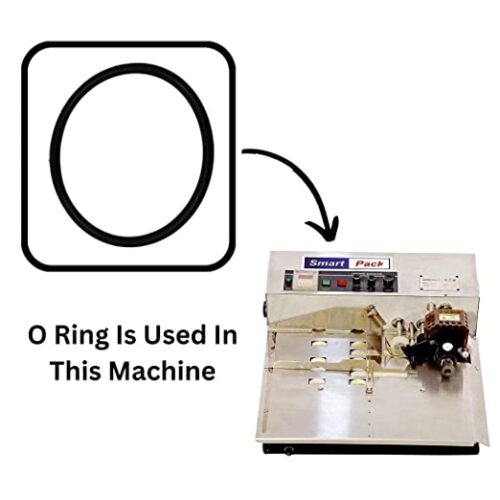

An O-ring for a high-speed batch coding machine serves as a crucial sealing component to prevent leakage and ensure proper functionality of the machine’s moving parts. Here’s a detailed description of its features and functionality:

- Sealing Function: O-rings are circular sealing elements typically made of rubber or elastomeric material. They are designed to fit into grooves or recesses and create a seal between two mating surfaces, preventing leakage of fluids or gases.

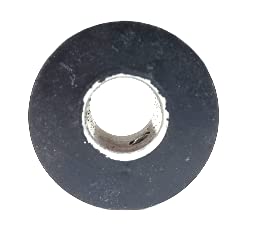

- Material Selection: O-rings used in high-speed batch coding machines are often made from materials such as nitrile rubber (NBR), silicone rubber (VMQ), or fluorocarbon rubber (FKM). The choice of material depends on factors such as the temperature, pressure, and compatibility with the substances being sealed.

- Size and Dimensions: O-rings are available in various sizes and dimensions to fit different sealing requirements within the batch coding machine. They come in standard sizes specified by international standards such as AS568 (United States) or ISO 3601 (International Organization for Standardization).

- High-Speed Operation Compatibility: O-rings used in high-speed batch coding machines are designed to withstand the dynamic forces and rapid movements associated with high-speed operation. They must maintain their sealing integrity and durability even under continuous motion and vibration.

- Resistance to Wear and Tear: Given the high-speed operation of the batch coding machine, O-rings must exhibit resistance to wear, abrasion, and fatigue. High-quality materials and manufacturing processes ensure longevity and reliability, reducing the need for frequent replacement and maintenance.

- Chemical Resistance: O-rings may come into contact with various chemicals, solvents, or inks used in the batch coding process. Therefore, they must demonstrate resistance to chemical degradation and maintain their sealing properties when exposed to these substances.

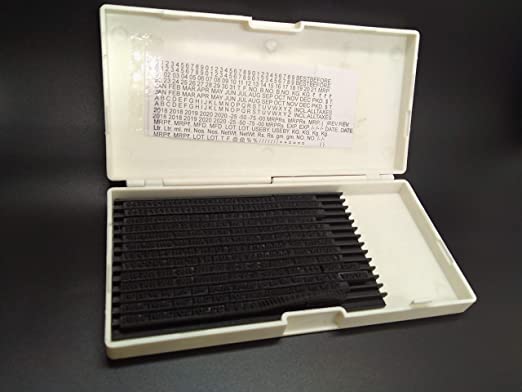

- Installation and Replacement: O-rings are relatively easy to install and replace within the batch coding machine. They can be stretched or compressed to fit into the sealing grooves or recesses without requiring specialized tools or equipment.

- Prevention of Contamination: In batch coding machines where ink or other fluids are used, O-rings help prevent contamination of the printing mechanism by sealing off sensitive components from external contaminants.

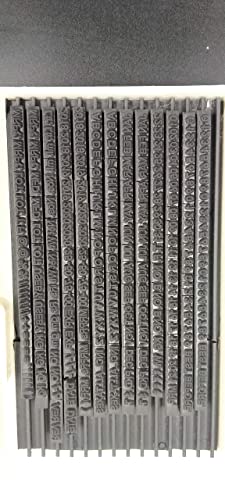

Overall, O-rings play a critical role in maintaining the performance and efficiency of high-speed batch coding machines by providing reliable sealing solutions for moving parts and critical components. Their quality, compatibility, and resistance to wear ensure smooth operation and consistent batch coding output.

Reviews

There are no reviews yet.